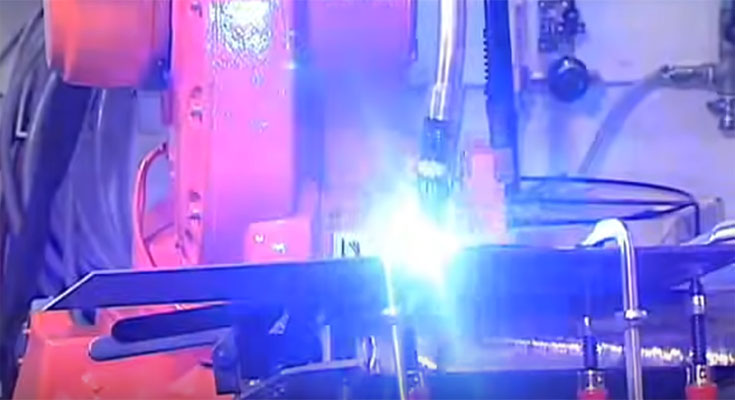

Robotic systems also work accurately with minimal splashes, shortening post-work cleaning time. In general, they improve customer satisfaction, because you can perform tasks faster, improving your reputation and gradually your result. In light of the boundaries of human welders, the benefits of welding automation are clear. These properties enable a modern robot to weld a complex part with multiple welds with a very high-quality level repeatedly.

Robotic welding is an automated process that increases efficiency, consistency, and ROI Slaughter automation through robot welding processes can minimize the risk of errors, increase welding efficiency and precision, and achieve economies of scale over time. By incorporating robotics into welding operations, manufacturers are allowed to protect workers and benefit from increased Welding Automation productivity. The American Welding Society offers certifications for manual welding and robotic arm welding. Robotic welding arm operators learn how to teach the automated system to move the arm, how to change the system parameters and how to program the welding arm to perform different processes.

As an automated welding process, robot welding improves safety, increases welding accuracy, and shortens project duration. These advantages and many others make automated robot welding ideal for a wide range of applications, especially compared to manual welding processes. This page discusses how welding automation works, the benefits, and what some of the typical use cases are. Higher welding quality: automating a welding process removes the biggest obstacle to welding quality, which is a human error. Most robot-welding operators and CNC Machining operators need to obtain professional certification to ensure they understand how to program machines and complete projects profitably and quickly. They also perform tasks with high precision, eliminating the need to repeat tasks, and wasting some time. Unlike manual welding, which depends on human workers, robot systems do not stop for breaks, holidays, or sick days. Once you have mastered the installation and planning required for each weld, you could use the systems all day long so you can increase productivity and easily meet customer deadlines.

Modern welding robots can also be equipped with vision and touch sensors to perform consistent, high-quality welding while monitoring the quality of their work. This allows almost all-welded units to be verified for quality, which is an important indirect advantage of welding automation. Normally, human quality control can only verify small batches of products and lose errors in uncontrolled products.