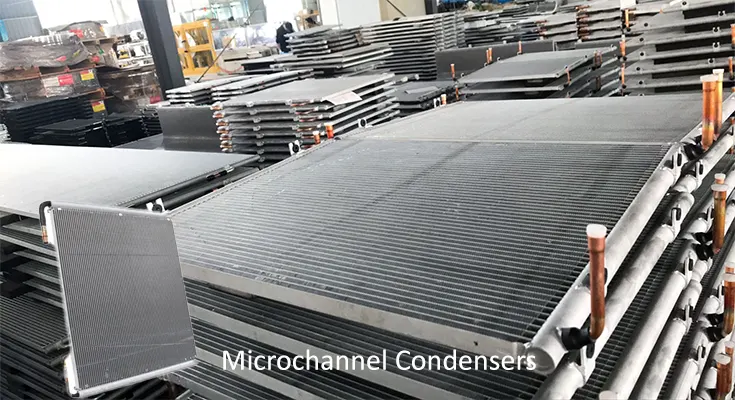

Microchannel condensers are a mainstay of modern HVAC and refrigeration systems, providing a reduced footprint, high performance, and reduced refrigerant usage compared to conventional condensers. When paired with chilled water coils, their design must be given serious consideration in order to enhance long-term operation, system compatibility, and overall efficiency.

Optimizing Heat Transfer

One of the main goals in the design of microchannel condensers is the optimization of heat transfer. The units are designed around flat aluminum tubes with extremely small internal channels and louvered fins for improved thermal performance. This design has the potential to improve heat exchange by up to 40% compared to traditional finned-tube designs. The louvers also reduce air resistance, allowing smaller fans to be used without loss of airflow.

When adding a chilled water coil to the system, its design needs to be compatible with the condenser. The coil typically accepts heat from the air and rejects it to the chilled water, and therefore its design—e.g., fin spacing and tube arrangement—needs to be compatible with the airflow and load requirements of the condenser. Programs like Kaltra’s MCHEselect can help engineers find the optimum balance between pressure drop and performance so that both components can work in harmony.

Managing Refrigerant Charge

One of the main advantages of microchannel condensers is that they can be run with much less refrigerant—up to 60% less than conventional units. This is due to the small internal volume of the microchannels. Nevertheless, when you add a chilled water coil to the system, the system must still operate effectively with low refrigerant flow.

For example, in ammonia-based cooling systems, it is desirable to maintain a low refrigerant charge for safety and environmental reasons. In such cases, the coil material and design play a crucial role. Copper or aluminum tubing with special surfaces would be chosen to promote good heat transfer. Even distribution of the refrigerant in the coil is also crucial, and hence some microchannel heat exchangers have distributors integral with them to avoid maldistribution of flow.

Choosing the Right Materials

Materials are also an important factor, especially when microchannel condensers are being combined with chilled water coils. Most microchannel heat exchangers (MCHEs) are made of corrosion-resistant aluminum alloys, such as AA3F05, which naturally form an oxide coating to protect against rust and wear. Chilled water coils, however, are often made from copper or stainless steel, which can present galvanic corrosion risks in humid or salty environments.

To prevent this, manufacturers apply protective coatings—like nanoscale or epoxy e-coatings—on the coil as well as the condenser. These coatings significantly increase service life, particularly in poor conditions like coastal or industrial environments. Hydrophilic coatings on the chilled water side also help with improved condensation drainage, which reduces the possibility of fouling and corrosion.

Fitting Everything Together

Space constraints are a common problem in modern cooling systems. That’s where the compact nature of microchannel condensers is useful—it’s about 20% smaller and half the weight of traditional units. It’s ideal for rooftop units, modular chillers, and other tight installations.

But when combining them with chilled water coils, designers need to make both parts work together without a compromise in performance. Airflow coordination is the key. The louvered fins of the condenser reduce air resistance, which allows smaller fans to be used. At the same time, the coil should not present too great a pressure drop. Computational fluid dynamics (CFD) modeling is usually utilized to tune these interactions and maximize system performance.

Supporting Low-GWP Refrigerants

As climate impact concerns continue to escalate, microchannel condensers are increasingly being designed to operate with low-global-warming-potential (GWP) refrigerants like R32, ammonia, and CO₂. Each of these has its own challenges—CO₂ is under very high pressure, and ammonia is corrosive.

In ammonia systems, for example, stainless steel tubing can be favored for the chilled water coil, whereas the microchannel condenser is based on corrosion-resistant alloys and protective coatings. This provides safe and efficient operation in the long term, satisfying both regulatory and performance requirements.

Ensuring Long-Term Reliability

Reliability and maintainability should not be overlooked. While materials and coatings in microchannel condensers reduce the potential for corrosion and fouling, the chilled water coil should also be easy to clean and inspect. Scaling or biofilm growth on the coil can degrade the performance instantly, so hydrophilic coatings are typically used to enable quick condensate drainage.

Sealing and connection points is another factor. Brazed construction facilitates the removal of leak paths in the condenser, and material selection for coil connections is carefully made for compatibility and durability. The outcome is a system that runs efficiently with minimal downtime.

Real-World Applications

Microchannel condensers paired with chilled water coils today are being applied in a wide range of applications:

- Commercial HVAC : Compact air-cooled chillers efficiently cool office buildings and shopping malls.

- Data Centers : High-density server rooms have precise temperature control with integrated MCHE and coil configurations.

- Industrial Cooling : Heavy-duty, corrosion-resistant systems provide process cooling in chemical plants and food processing plants.

Economic and Environmental Benefits

The combination of these two factors provides more than engineering advantages:

- Energy Efficiency : Enhanced heat transfer reduces compressor and fan power consumption.

- Sustainability : Low refrigerant charges and adaptability to green refrigerants reduce environmental impact.

- Cost Savings : Space-saving design and longer service life lower installation and maintenance costs.

- Durability : Corrosion resistance prolongs equipment life, promoting sustainable use of resources.

- Case Example: Office Building Chiller Upgrade

A complex of office buildings recently retrofitted its cooling system with an air-cooled chiller that has a microchannel condenser and chilled water coil. With the low refrigerant charge and high-efficiency design, the new system had 20% less energy consumption than the previous system. The coil was antifouled with a hydrophilic coating, and the condenser was protected from urban pollutants with a nanoscale protective coating. The result was a quieter, greener, and more dependable cooling solution with proven cost savings.

Final Thoughts

Prescribing microchannel condensers for chilled water coil applications is not a task of technical specification matching alone—it is a task of creating a well-balanced, long-lasting, and high-performance system. Through careful selection of materials, proper integration, and attention to airflow and refrigerant management, these systems can offer peak performance in a variety of applications. With sustainability taking a front seat in building and industrial design, microchannel condensers will continue to play an integral role in the future of cooling technology.