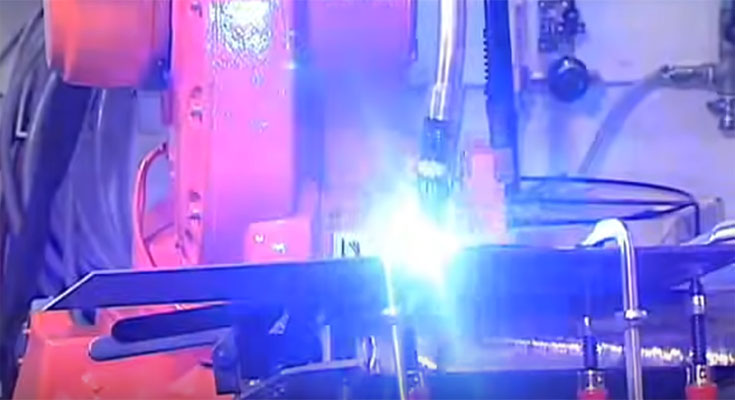

Robotic Welding Pros and Cons

Robotic systems also work accurately with minimal splashes, shortening post-work cleaning time. In general, they improve customer satisfaction, because you can perform tasks faster, improving your reputation and gradually your result. In light of the boundaries of human welders, the benefits of welding automation are clear. These properties enable a modern robot to weld a complex part with multiple welds with a very high-quality level repeatedly.

Robotic welding is an automated process that increases efficiency, consistency, and ROI Slaughter automation through robot welding processes can minimize the risk of errors, increase welding efficiency and precision, and achieve economies of scale over time. By incorporating robotics into welding operations, manufacturers are allowed to protect workers and benefit from increased Welding Automation productivity. The American Welding Society offers certifications for manual welding and robotic arm welding. Robotic welding arm operators learn how to teach the automated system to move the arm, how …

Robotic Welding Pros and Cons Read More